PET packaging lebanta la tlhahiso ea line

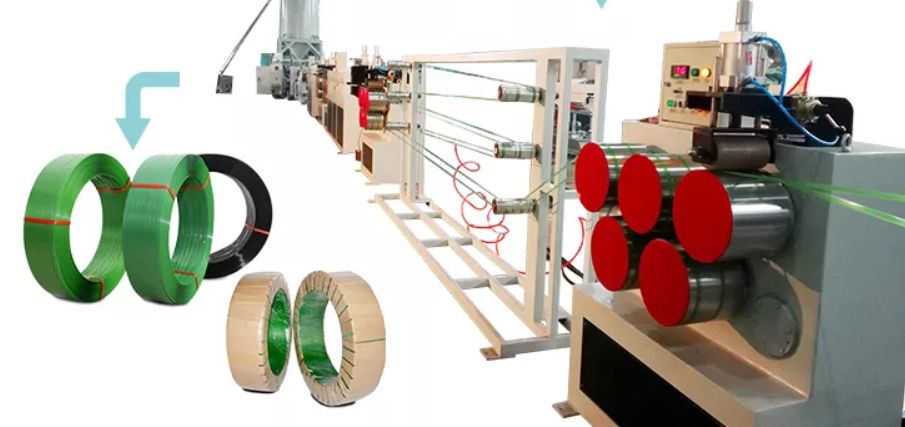

I. Litekanyetso tsa mantlha:

Ho sebetsa: 100% botlolo ea PET kapa e ncha (viscosity 0.75 kapa ho feta)

Litekanyetso tsa tekheniki bakeng sa lisebelisoa tse tala

| Lintho tse tala A: 100% | |

| cycle stock | Likaroloana tsa PET botlolo ea chip |

| Sebopeho sa thepa e tala | Boholo ba bophara ba 8-10mm |

| botenya | > 400micron |

| IV | 0.75-0.9dl/g |

| tekano | 0.35-0.40kg/dm3 |

| Metsi a pele | <1% |

Tlhaloso ea bophara ba 9-19mm (tloaelo ea rona)

Sephutheloana lebanta botenya ba 0.6-1.2mm

matla a ho robeha <40-45kg/mm²

katoloso 10-15%

Hlakola tse peli feela

Molumo oa Extrusion, Max.180-220Kg/h

Lebelo la mohala ke 120m / min 2

Phepelo ea motlakase e sebetsang ke AC 380v / 3HP / 60Hz

e kentsoeng matla a 152kw (matla a ho sebetsa a ka bang 95kW)

Basebetsi, batho ba 1-2

Kakaretso ea boholo: 40m×2m×3.5m

Ea bobeli, sehlopha sa lihlahisoa tsa lihlahisoa

| nomoro ea odara | lebitso | mohlala | bongata | litlhaloso |

| 1 | Omisa tsamaiso ea precrystallization | 1500L | 2 sete | |

| 2 | dehumidifier | 1 sete | ||

| 3 | sekrufuru se le seng sa extruder | SJ-90/30 | 1 sete | |

| 4 | Kholomo e fetola nete | 1 sete | ||

| 5 | pompo ea molumo e laoloang | 1 sete | ||

| 6 | Flow der head (mold) | 1 sete | ||

| 7 | bosh | 1 sete | ||

| 8 | Preheater ea pele ea li-roll tse hlano | 1 sete | ||

| 9 | Setofo sa tensile (lebokose le futhumatsang) | 1 sete | ||

| 10 | Mochine oa pele oa ho otlolla | 1 sete | ||

| 11 | Mochine oa bobeli o otlolohileng | 1 sete | ||

| 12 | leloala la chelete | 1 sete | ||

| 13 | Tobetsa sesebelisoa sa ho beha mocheso | 1 sete | ||

| 14 | bosh | 1 sete | ||

| 15 | Terekere ea lirolara tse tharo | 1 sete | ||

| 16 | PLCDual-station winder | 2 sete | ||

| 17 | tsamaiso ea motlakase | 1 sete |

| 1. E entsoe ka tšepe e sa hloekang ea 202 #, e nang le sebopeho sa 'mele oa barrel habeli, 1.5MM² lera e kahare, 1.5MM² ea kantle, 'me fensetere e bonoang e kentsoe 'meleng oa moqomo. | |||||

| 2. Motlakase oa se omisang ke 1200KG, matla a futhumatsang a motlakase ke 4KW, 'me matla a motlakase a kopanyang ke 5.5KW. | |||||

| 3. Sebelisa 3HP deceleration motor ho potoloha |

|

|

| ||

| 4. E na le scaffolding, e entsoeng ka poleiti e batang ea 3.0T |

|

| |||

| 5. Botlaaseng bo na le thepa e otlolohileng ea ho hula thepa |

|

|

| ||

| 6. Hloekisa moralo oa monyako 'me u hloekise lemati |

|

| |||

| 7. Molamu o kopanyang o bohareng o nka ¢ phala ea 50 ea tšepe e sa tsitsang, 'me lehare la ho kopanya le entsoe ka poleiti ea tšepe e matlafalitsoeng ea 3.0. | |||||

| 8. Adopt Huawei mocheso o potolohang fan e le mohloli oa phetisetso ea moea o chesang |

|

| |||

| 9. Kenya 50 ~ 300℃ tšireletso ea mocheso o feteletseng |

|

|

| ||

| 10. Sebelisa taolo ea liphanele tsa elektronike, ts'ebetso ea othomathike le e tloaelehileng, letsatsi le leng le le leng ka hare ho 24 e nyenyane e qalang e fetohang |

| ||||

| 11. Ho na le sesupo sa khefu le ho chesa haholo, 'me ho kheloha ha mocheso oa mokhoa oa ho laola mocheso oa PID ho nyane. |

|

| |||

| 12. Moralo oa mofuta o fokang ho etsa hore mocheso o be o ts'oanang |

|

|

| ||

13. Maemo a tsamaiso ea tsamaiso

| 1 | Matla a motlakase | AC 415V±10% 60HZ 3P+N |

| 2 | metsi a phodileng | ~20℃ 0.2 ~ 0.3Mpa 300L/min |

| 3 | Lisebelisoa tse ommeng | Metsi a ne a le 0.45% pele PET e omisoa |

14. Bokhoni ba tlhahiso

| 1 | matla a ho omisa | PET 500Kg / h (bophahamo ba pokello: 0.5T / m³) |

| 2 | bokgoni ba phano | PET≥500Kg/h |

| 3 | Sebaka sa phetisetso | L≥6m H≥6m |

| 4 | Seboka sa ho kenya | Ka tlung 0 ℃ ~ 30 ℃, mongobo o lekanyelitsoeng 20% ~ 70% |

| 5 | 'Mala oa lisebelisoa | KH 'Mala o tloaelehileng kapa litlhoko tsa mosebelisi |

1) dehumidifier

|

| |||

| Tšebeliso ea matla ea moea o nchafatsang moea ke 2.2KW, 'me tšebeliso ea matla ke 20KW | ||||

| 3. Automatic microcomputer digital controller ka fumana botsitso ba phoka moea o omileng. | ||||

| 4. Amohela mokhoa oa ho bonts'a sebopeho sa LED le ts'ebetso ea othomathike ea phoso. |

| |||

| 5. Sweden e rekisitse mabili a tlosa mongobo a nang le bophelo bo bolelele ba tšebeletso. |

| |||

| 6. E loketse bakeng sa antipyretic e tloaelehileng le ea optical le ho omisa. |

|

| ||

| 7. Motor reverse phase le tšireletso ea overload. |

|

| ||

| 8. E na le alamo ea mocheso o feteletseng le ts'ebetso ea ho bonts'a phoso, sebopeho se bonolo sa ka hare, tlase ea phoso, tlhokomelo e bonolo. | ||||

| 9. Sebelisa fan ea khatello e phahameng e le mohloli oa ho potoloha le ho tsosolosa moea oa khatello ea moea ho netefatsa ts'ebetso e tloaelehileng ea mochine. | ||||

Mochini ona o sebelisoa haholo ho etsa lesela la liphoofolo tse ruuoang lapeng, lesela la ho paka.

Amohela plc laola mohala kaofela etsa tlhahiso ea automatic

e sebelisa pompo e qhibilihisang le sensor ea khatello e netefatsa hore tlhahiso e tsitsitse le taolo ea boleng ba likhoele

Thepa e tala eo u ka e sebelisang ke 100% ea li-flakes tsa liphoofolo tse ruuoang lapeng tse nchafalitsoeng ho tsoa libotlolong tsa liphoofotsoana, kapa lisebelisoa tse sa tsoakoang kapa tse kopantsoeng.

Molemo:

1.Sebelisa 100% Recycled PET Flakes ho fokotsa litšenyehelo

2.Good dehumidifer drying system(Crystallization system optional) ho etsa bonnete ba hore thepa e omisitsoeng e lekana ho hlahisa likhoele tsa boleng bo holimo.

3.Moqapi o khethehileng o chesang o etsa tanka ea tensile ho etsa sebopeho se setle, bophara bo lekanang, lesela le otlolohileng

3)cylindrical net phetoho

Sebaka sa ho futhumatsa 2

Matla a ho futhumatsa:, 2KW 2

lintho tse bonahalang: PET (letlapa la botlolo) (0.7-0.95)

Boemo ba sefe: 40 / 80 / 120 mesh (425 / 180 / 125um)

4) Pompo ea ho lekanya

'Mele oa pompo: mocha o phallang ka hare oa tšepe ea nitride bakeng sa phekolo ea seipone

Gear: leino sebopeho meno a otlolohileng kapa oblique meno sesebelisoa tšepe / motsoako o khethehileng bakeng sa kalafo seipone

Sleeve sa Shaft: tšepe ea sesebelisoa / motsoako o khethehileng

Mokhoa oa ho futhumatsa: Ho futhumatsa metsi a potolohang

Mokhoa oa ho pholisa: Sisteme ea ho futhumatsa ea shaft-end

Axis shape: biaxial drive, pholileng ka metsi

Axial seal: ho tsoa ha spiral

5)Hlooho ea mochini oa ho phalla (mold)

E entsoe ka tšepe ea boleng bo holimo, sebopeho sa compact, khokahano e utloahalang le sebaka se loketseng.Tlosa molomo oa hlobo ho hlahisa lihlahisoa tse khethehileng tsa 9-19mm.

Phallo kanale holim plating ka thata chromium le ho bentsa kalafo, botenya 0.03-0.05mm, thata HRC50-60, bentsa ho nepahala 0.02-0.06um.

Sebaka se ka ntle ke chrome plated layer 0.02-0.03mm bakeng sa tlhokomelo e bonolo le thibelo ea mafome.

Palo ea lihlopha: 2 strips

Molamu o futhumatsang oa tšepe o se nang tšepe o futhumatsang ka hare, tšepe e sa hloekang e futhumatsang lesale la ho futhumatsa molala, matla a 4kW.

Sebaka sa ho bala se utloang khatello ea maikutlo sa 0-350bar

7) Sekoahelo se pholileng

Litokiso tse tlase: ho phahamisa ka letsoho

Sebaka sa taolo ea mocheso (bongata) 1

Peipi e futhumatsang ea tšepe e sa hloekang le thebe ea tšepe e sa hloekang

Likarolo tsohle tse amanang le metsi li entsoe ka tšepe e sa hloekang ea 304

8)Terekere ea pele le ea lirolara tse tharo

Bakeng sa ho otlolla pele ho futhumatsa, e entsoe ka enjene, se fokotsang, lirolara tse tharo tsa tšepe le lisebelisoa tsa phetiso.Taolo ea lebelo la ho sokoloha khafetsa, phetisetso ea gear ea oblique ke lerata le tlase, phetisetso e boreleli.

Mokhoa oa phetisetso ea enjene: turbine turborod

The clamp roller e bophara ba 120mm, e nang le mocheso o phahameng oa rabara le ho koala ka mochine.

9)Setofo sa tensile (lebokose le futhumatsang)

Lebokose la ho futhumatsa haholo le phethela ho futhumala ha PET ka mor'a ho bōptjoa.Lebelo la ho futhumatsa le potlakile, le ka phethelang kapele mokhoa oa ho otlolla sehlopha sa PET.

Matla a ho futhumatsa ke 10.5kW

Phapang ea mocheso (℃), + / -1℃

Sebaka sa taolo ea mocheso 1

10)Mochini oa pele oa ho otlolla

Bakeng sa ho otlolla ka mor'a ho futhumatsa, e entsoeng ka enjene, se fokotsang, lirolara tse hlano tsa tšepe le likere tsa phetiso.Taolo ea lebelo la ho sokoloha khafetsa, phetisetso ea gear ea oblique ke lerata le tlase, phetisetso e boreleli.

Tafole ea rolara e koahetsoe ka botlalo ka kalafo e thata ea chromium sandblasting

The clamp roller e bophara ba 120mm, e nang le mocheso o phahameng oa rabara le ho koala ka mochine.

11)Mochini oa bobeli o otlollang

Bakeng sa ho otlolla ka mor'a ho futhumatsa, e entsoeng ka enjene, se fokotsang, lirolara tse hlano tsa tšepe le likere tsa phetiso.Phetiso ea lebelo la phetoho ea lebelo la oblique ke lerata le tlase, phetiso e boreleli.

Tafole ea rolara e koahetsoe ka botlalo ka kalafo e thata ea chromium sandblasting

Matla a enjene ea ho fetola maqhubu a AC ke 11kw

The clamp roller e bophara ba 120mm, e nang le mocheso o phahameng oa rabara le ho koala ka mochine.

12)Khatiso ea lipalesa

Mochine oa khatiso o hatella holim'a lebanta la ho paka la PET ho ntlafatsa matla a ka morao le ho ferekana ha holim'a lebanta.

E na le likarolo tse latelang

-Kaho ea 'mele e cheselitsoeng ka tšepe

-Carburized tšepe moqolo holimo le tlaase

-Roller bophara ba 150mm, phekolo ea holim'a rolara ea HRC55-60.

-Bophara bo sebetsang, 220mm

-Frequency conversion AC motor ke 5.5KW

- Lebelo la mohala: 140m / min

U sebelisa hydraulic drive, embossing e bonolo ebile e bonolo ho sebetsa

13) Tiisa sesebelisoa sa ho beha mocheso

Ho tiisa ho chesa ho sebelisoa bakeng sa tlhophiso e chesang e potlakileng ea PET band kamora ho tsitsipana, ho thibela ho felisoa ha khatello ea maikutlo ka hare ho sehlopha sa PET kamora ho ts'oaroa ha tsitsipano le ho tsitsisa boholo ba PET band.

13)Tanka ea metsi a pholileng

Tanka e pholileng e sebelisetsoa ho laola ho pholile ho feletseng le kristalline ea lebanta la ho paka le ho netefatsa botsitso ba boholo ba lebanta la ho paka.E entsoe ka tšepe e sa hloekang.

Sebaka se phodileng: metsi

Bolelele ba sink ke 4,000mm

15) Terekere ea lirolara tse tharo

Bakeng sa ho hula le ho otlolla lebanta la PET ka mor'a ho tiisa mocheso oa mocheso le ho pholile.E entsoe ka enjene, se fokotsang, roller le lisebelisoa tsa phetisetso, lebokose lohle la phetisetso, ha ho na deformation, lerata le tlase la phetisetso ea gear, phetiso e boreleli.

16)PLCMechini e 'meli ea plex

Bakeng sa meqolo ea lihlahisoa, setsi se hlophisa melumo ka bo eona.E na le ho amohela li-coil, coil core, sesebelisoa sa koloi, sesebelisoa sa wiring, rack, taolo ea motlakase, joalo-joalo.

PET e na le cartridge e tloaelehileng ea pampiri

Sebopeho sa rolling receiver:

Sebopeho sa mofuta oa Nacelle

Bophara bo lekantsoeng ba tube ea pampiri ke 406mm

17) Tsamaiso ea tsamaiso ea motlakase

frequency transformer: ABB

Metara ea taolo ea mocheso: Omron

Bahokahanyi: Siemens

Thepa skrine: Siemens

Enjene e kholo: Siemens