Mohala oa tlhahiso ea extrusion pipe ea HDPE

40-160mm MPP Pipe Electric Tube Plastic Single Screw Extruder Machine Production Line

| NO. | Lebitso | Bongata |

| 1 | Sesebelisoa se le seng sa screw extruder se nang le sesebelisoa sa ho fepa ka boiketsetso | 1set/2sets |

| 2 | Hlobo | 1 sete |

| 3 | Vacuum Calibrating le Cooling Tank | 1set/2sets |

| 4 | Tlosa mochini | 1 sete |

| 5 | Mochini oa ho itšeha | 1set/2sets |

| 6 | Stacker | 1 sete |

1.40-160mm MPP Pipe Electric Tube Plastic Single Screw Extruder Machine Production Line Single screw extruder e nang le sesebelisoa sa ho iphepa ka boiketsetso.

(1) Letšoao la likoloi: Siemens kapa mofuta o mong o tummeng oa China

(2) Letšoao la inverter: ABB/DELTA /SINEE

(3) Letšoao la Contactor: Siemens / DELTA

(4) Letšoao la Relay:Omron/DELTA

(5) Letšoao la ho senya: Schneider/DELTA

(6) Mokhoa oa ho futhumatsa: Ceramic kapa cast

2.40-160mm MPP Pipe Motlakase Tube

Plastic Single Screw Extruder Machine Production LineVacuum calibrating le tanka ea ho futhumatsa metsi

(1) Matla a pompo ea vacuum: 4 kw

(2) Matla a pompo ea metsi: 4 kw

(3) Boitsebiso: Tšepe e sa hloekang

(4) Mokhoa: Ho fafatsa ka likhoka

(5) Diameter: E hlophisitsoe

(6) Bolelele ba tanka: 6 m

SJ Series Single Screw Extruder e sebelisoa haholo ho sebetsana le PP, PE, PPR, ABS le lipolasetiki tse ling.E na le mechini e thusang, e ka etsa profil, liphaephe, maqephe le lihlahisoa tse ling tsa polasetiki le granulation.Sena se Single Screw Extruder se na le molemo oa mokhoa o bonolo oa tlhahiso ea theknoloji, tlhahiso e phahameng, boleng bo tsitsitseng le theko e tlaase. E loketse lisebelisoa tse sa tšoaneng tsa polyolefin: HDPE, PPR, PP, le ABS joalo-joalo.

Molemo o ka sehloohong

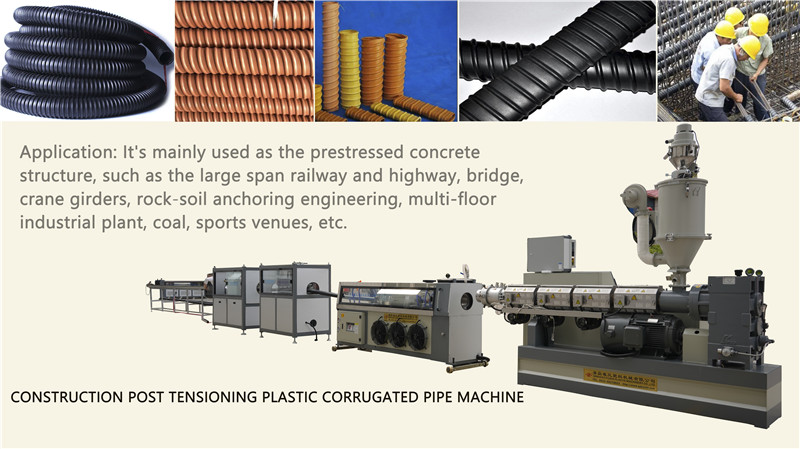

1.Mofuta ona oa liphaephe o na le melemo e mengata, joalo ka leseli le thibelang kutu, ho le bonolo ho lokisa, nako e telele ea ho e sebelisa joalo-joalo.

2.Liphaephe li sebelisoa haholo ka litsela tse phahameng, kaho ea masepala, lifolete joalo-joalo.

Mohala oa ts'ebetso

Raw material+ Master Batches → Ho Kopanya → Vacuum Feeder → Plastic Hopper Drier→ Sekerufu se le seng sa scruder → Co-extruder bakeng sa khoele ea mebala le Mekhahlelo e Mengata → Mould → Vacuum Calibration Tank → Fafatsa Tanka ea Metsi a Pholisang → Tlosa → Ha ho Sekha Lerōle → Habeli/E le 'Ngoe disc Winding/ Stacker → Tlhahlobo ea ho qetela ea sehlahisoa le ho paka

Re latela mofuta oa khoebo oa Jeremane joalo ka morekisi ea tšepahalang oa lefats'e ka bophara oa mohala oa polasetiki oa extrusion.Re se re fane ka mela e fetang 1000 e fumanehang linaheng tse ngata hobane re fana ka theknoloji ea morao-rao, mochine o tšoanelehang, karolo e ka tšeptjoang le tšebeletso e ntle ka ho fetisisa ka mor'a thekiso.

Rala le ho u etsetsa mochini o loketseng.

2. Pele ho pepa, re tla leka mochine ho fihlela u khotsofetse ka ho feletseng.(U ka tla fekthering ea rona ho tla hlahloba mohala oa tlhahiso.)

3. Phano.

4. Re tla fana ka tšebeletso ea ka mor'a thekiso:

(1) Ho kenngoa ha masimo le ho laela;

(2) Koetlisa basebetsi ba hao tšimong;(3) Tšebeletso ea ho lokisa le ho lokisa tšimo;

(4) Likarolo tsa Mahala tsa Spare ;

(5) Tšehetso ea theknoloji ea Video / Inthaneteng.

Mochini o etsang liphaephe tsa motlakase oa polasetiki oa thapo ea motlakase oa thapo ea motlakase oa MPP