QINGDAO CUISHI PLASTIC MACHINERY CO.,LTD

Granulator

Boleng bo phahameng bo phahameng tlhahiso e chesang ea polasetiki ea pellet/pipe/cubeextruder mochini oa thepa ea polasetiki ea botjha

SJ series single screw extruder plastic machine haholo-holo e sebetsa ho extrude PP, PE, PET, PVC, ABS, PS, PA ect material. E amohela lebokose le khethehileng la lisebelisoa, 'me e na le likarolo tsa lerata le tlaase, ho matha ho tsitsitseng, ho jara ho phahameng, bophelo bo bolelele ba tšebeletso. .E na le lisebelisoa tse fapaneng tsa hlobo le lisebelisoa tse thusang, e ka hlahisa pipe ea polasetiki, lakane, boto, granules joalo-joalo .E na le likarolo tsa mokhoa o bonolo, tlhahiso e phahameng, khatello e tsitsitseng ea extrusion, le litšenyehelo tse tlaase.

| Morero:DJ85 motho a le mong screw pelletizing line | |

| Lintho tse tala & foromo | Lifilimi tsa PE |

| Sehlahisoa sa ho qetela | PE granules |

| Bokhoni ba tlhahiso | 120-200kg/h , ho itšetlehile ka litšobotsi tsa thepa. |

| Bophahamo bo bohareng | 1.14m |

pp pelletizing line ea polasetiki e sebelisang botjha mochini oa granulating litšila tsa polasetiki tse etsang mochini

Litekanyetso (CSSeries Double Stage Compactor-Granulator):

| Mohlala(habeli sethaleng) | CS85-100 | CS100-120 | CS130-150 | CS160-180 | CS180-200 |

| Screw Diameter(mm) | 85 | 100 | 130 | 160 | 180 |

| L/D | 25-42 | 25-42 | 25-33 | 25-33 | 25-33 |

| Bokhoni(kg/h) | 150-200 | 300-350 | 500 | 600-700 | 800-1000 |

Kopo:

Filimi ea PE, PP, Silk, Flakes (≤0.5mm), Mekotla, joalo-joalo.

Hlokomela, rona CS letoto la compactor granulator e ka ba mokhoa oa ho itšeha, kapa mokhoa oa ho itšeha oa metsi bakeng sa khetho

E na le:

Conveyor ea lebanta(sebui sa tšepe) → Compactor → Main extruder(vacuum degassing system) → Hydraulic screen changer → Sub-extruder →

Mochine o fetolang skrineng sa Hydraulic → Sistimi ea ho itšeha ka selikalikoe sa metsi → Mochini o ntšang metsi → Sisteme ea ho otla moea → Sekoti sa polokelo → khabinete ea taolo

- Lintlha tse akaretsang

1.1Sebaka sa fatše

Kaho ea mantlha, mosebetsi oa lefatše, mosebetsi oa lebota o lokela ho phethoa hantle ke Moreki bakeng sa ho amohela mohala ona oa pelletizing.

Moreki o lokela ho fana ka li-crane, forklift kapa lisebelisoa tse ling tsa ho phahamisa, lisebelisoa le lisebelisoa.

Sebaka: ho raloa ho latela moralo oa mela.

1.2Phepelo ea motlakase

Matla a kentsoeng:106KW (tšebeliso ea matla e sebetsang e tla ba hoo e ka bang 70%)

Phepelo ea motlakase:

Matla a phepelo: 3 * 380V + N + PE;

Mamello ea motlakase: + 10%/-5%;

Matla a ho laola: 24VDC + 220VAC;

Hangata: 50Hz+-2%

Mohala/lithapo:

- Lithapo / lithapo ho tloha phepelong ea motlakase ho ea ho khabinete ea taolo (e fanoang ke Moreki).

- Lithapo tsohle tsa motlakase ho tloha ho khabinete ea taolo ho isa mochining o mong le o mong (o fanoeng ke Moreki).

1.3Phepelo ea metsi

Tšebeliso:0.6T/h (lisebelisoa tsa metsi)

Metsi a pholileng:

Ntle le liminerale tse qhibilihisitsoeng kapa tse emisitsoeng joalo ka phosphor, sebabole, tšepe, jj.

Mocheso oa mocheso oa T1: max.15 ℃

Mocheso o tsoang T2: T2=T1+5℃

Khatello ea ho kena, min: 2.5 bar

boima: 5-8ºdH;

Reflux: ntle le khatello

Hose ea metsi:

Ho tloha phepelong ea metsi ho isa mochining o mong le o mong (o fanoeng ke Moreki).

1.4Moea o hatisitsoeng:0.6M3/min, 0.4~0.7Mpa

1.5Basebetsi ba ts'ebetso

Batho ba 2-3

1.6Oli ea ho tlotsa

E fumanoe 'marakeng oa lehae ka khothaletso ea Morekisi (e fanoeng ke Moreki).

- Lipehelo tsa khoebo

2. 1Machine lethathamo & Theko

| Che. | Lebitso la Sesebelisoa | Mohlala | Bongata (sete) |

| 1 | Lebanta la conveyor |

| 1 |

| 2 | Sekontiri |

| 1 |

| 3 | DJ85/33ssekoti se se nang letho | DJ85/33 | 1 |

| 4 | Mofuta oa poleiti Hydraulic screen changer160 |

| 1 |

| 5 | Sistimi ea ho itšeha ka metsi |

| 1 |

| 6 | Mochini o thothomelang oa ho tlosa metsi skrineng |

| 1 |

| 7 | Silo |

| 1 |

| 8 | Motlakasekhabinete |

| 1 |

2.2Lipehelo tsa tefo

- 40% e le depositi ka T/T.

- 60% e le tekanyo ea T / T pele ho pepa le ka mor'a tlhahlobo.

2.3Nako ea thomello

Ka matsatsi a 50 ho tloha ka letsatsi la ho amohela depositi.

2.4Ho paka

Filimi ea polasetiki.

2.5Tiisetso

Likhoeli tse 13 bakeng sa likarolo tsa mochini ho tloha ka letsatsi la theko ea thepa.Tiisetso ea likhoeli tse tharo bakeng sa likarolo tsa motlakase haeba phepelo ea motlakase fekthering ea Moreki e sa tsitsa.

cuishi e tla lefisa theko ea theko ea Moreki ea likarolo tse ling ka mor'a hore thepa e tsoe ka waranti mme e fane ka tataiso ea nako e telele ea tekheniki.

2.6Ho kenya le ho Komisa

- Moreki o lokela ho itokisetsa ho kenngoa ha lisebelisoa li fihla, joalo ka phepelo ea motlakase, phepelo ea metsi, basebetsi le crane, jj.

- cuishi e tla itokisetsa kopo ea visa bakeng sa baenjiniere ba tla ea fekthering ea Moreki bakeng sa ho fana ka mosebetsi.

- Moreki o lokela ho lefella litekete tsa ho ea le ho khutla bakeng sa lienjineri haeba kopo ea visa e amohetsoe, le litšenyehelo tse hlahisoang ke libere joalo ka litloaelo tsa visa, lijo, bolulo le tumello ea USD100 ka letsatsi bakeng sa moenjiniere e mong le e mong.

2.7Ho nepahala

- Matsatsi a 60 ho tloha ka letsatsi la quotation.

3.Tlhaloso ea tekheniki

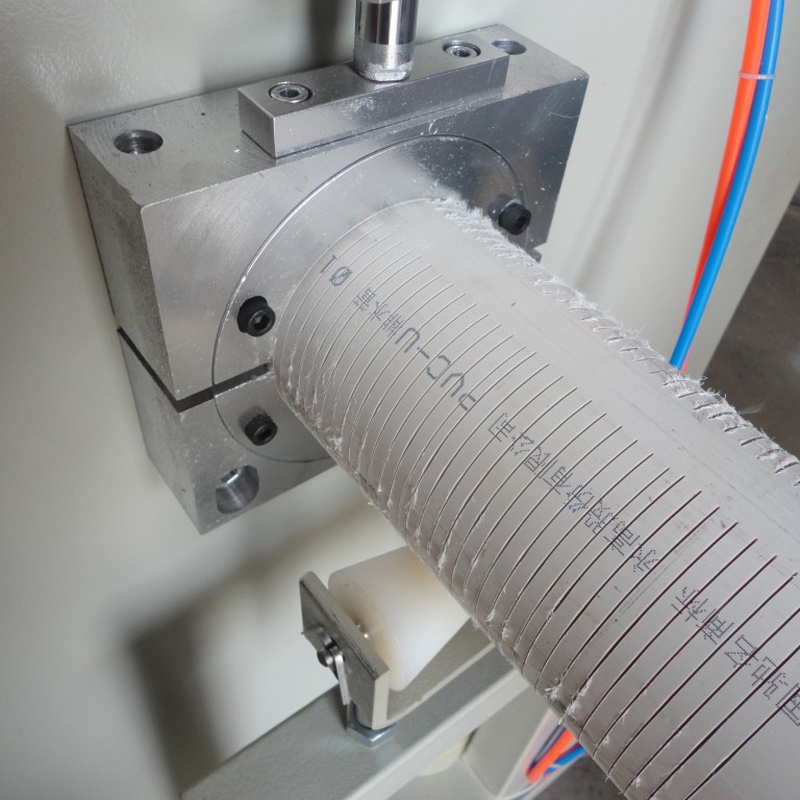

3.1DJ85 Sekoti se le seng sa screw extruder

5Sistimi ea ho itšeha ka metsi

lehare le die, mme kgatello ya thipa e ikamahanya le maemo etsa bonnete ba hore ho na le matla a tšoanang a ho itšeha a thipa. Qala tsamaiso ka senotlolo se le seng ho etsa hore tsamaiso eohle e sebetse haholoanyane e loketseng; Horizontal die face cutter Matla a seha: 2.2kw Matla a pompo ea metsi: 2.2kw The cutter ke taolo ea maqhubu ka inverter | |

| 6 | Mochini o thothomelang oa ho tlosa metsi skrineng |

Sesene sa ho thothomela se tsoetseng pele se kopantsoeng le ho omisa centrifugal se tšekaletseng se ka fihlela ts'ebetso e ntle ea ho omisa le tšebeliso e tlase ea matla.cuishi e nka moralo o koetsoeng mme e na le sekoaelo se sa utloeng molumo, se nang le lerata le tlase ebile se bonolo ho basebelisi.

Matla a motlakase: 0.25kw*2. Likarolo tse amanang le metsi: SUS304. Kopanya li-sieves: ha li chesetsoe.E kentsoe le ho ts'oaroa ka li-screws, bakeng sa ho nkela li-sieve tse ncha sebaka nakong e tlang. Liliba li pota-potiloe ka rabara, ho thibela phapang e khōlō ea amplitude e bakoang ke botsofali ba selemo. Moralo o khethehileng oa ho thibela litšila tse nyane ho oela pompong ea metsi.

Matla a motlakase: 3kw. Lebelo la ho potoloha: 1460rpm Likarolo tse amanang le metsi le granules: SUS304. | |

| 7 | Silo |

| Matla a sebetsang: 700LThepa ea karolo e amanang le thepa Stainless steel | |

| 8 | Motlakasekhabinete |

Sistimi ea taolo e amohela Nokiacontrol, 'me e na le skrine ea ts'ebetso ea boemo ba indasteri (ntho ea boikhethelo)

Ho ea ka tatellano e hlophisitsoeng e hlophisitsoeng le litlhoko tsa ts'ebetso ea ho sebetsana le thepa, tsamaiso ea cuishi e hokahaneng e hlokomela ho qalisa senotlolo se le seng, ka hona ho qoba liphoso ts'ebetsong ea ho qala ka letsoho.

Ka thuso ea yuniti e ikhethileng ka ho khetheha, sistimi ea cuishi e ka lemoha senotlolo se le seng sa mojule oa sistimi eohle ho qoba tšenyo ea lisebelisoa e bakoang ke ts'ebetso e fosahetseng nakong ea ho koala ka letsoho.

cuishi e na le ts'ebetso ea ho emisa ts'ohanyetso, e sebelisoang e le boemo ba tšohanyetso bakeng sa likotsi tse sa tsitsang nakong ea ts'ebetso ea mochine, ho koala tsamaiso eohle ka potlako le ka potlako ho qoba likotsi tsa bobeli le likotsi.

Sesebelisoa sa tšireletso ea bophelo Sistimi ea cuishi e nka ka botlalo litaba tsa polokeho ea lisebelisoa nakong ea ts'ebetso.Seteishene se seng le se seng sa ts'ebetso le sebaka se potolohang se na le lisebelisoa tsa ts'ireletso ea elektroniki ho netefatsa polokeho ea lisebelisoa nakong ea ts'ebetso le ho qoba likotsi tse ka bang teng nakong ea ts'ebetso ea lisebelisoa ho baka kotsi ho basebelisi ba bareki.

Ka thuso ea mokhoa o nepahetseng oa ho laola mocheso le moralo o lebisitsoeng oa optimization oa karolo ea polasetiki ea polasetiki, tsamaiso ea cuishi e ka netefatsa ho tšepahala le botsitso ba boleng ba ho qetela ba pelleting.

Ka thuso ea molao-motheo oa taolo ea modular le temohisiso e felletseng ea ts'ebetso ea lisebelisoa tse fapaneng tse tsosolositsoeng, sistimi ea cuishi e ka etsa bonnete ba hore litšila tse sebetsitsoeng li fihlela boemo bo nepahetseng ba ho futhumatsa le ho kopanya ka phapusing ea compaction, 'me li ka qoba hore thepa ea ho khutla ea polasetiki e se ke ea kopanngoa. .Ho chesa ka ho feteletseng kapa ho senyeha ha setoro. Motsamaisi: Schneider Tlhaloso: CHNT Phetoho e akaretsang: CHNT Sekoahelo sa potoloho: CHNT Tlhokomeliso: Moreki o hloka ho fana ka terata ho tloha khabineteng ea taolo ho mochini o mong le o mong.

|

3.2 Karolo e Ikemetsengs: FOC

Karolo ea mochini

| No | Lebitso | Yuniti | Qty |

| 1 | Lehare le chesang | likotoana | 2 |

| 2 | Sesebelisoa sa ho tlosa screw | beha | 1 |

| 3 | Liatlana tsa asbestos | para | 1 |

| 4 | Setiiso sa oli ea shaft e kenyang le ho tsoa | beha | 1 |

| 5 | Vacuum O-ring | likotoana | 2 |

Likarolo tsa motlakase

| No | Lebitso | Yuniti | Qty |

| 1 | Khokahano ea AC | likotoana | 1 |

| 2 | Konopo | likotoana | 2 |

| 3 | Tafole ea mocheso | likotoana | 1 |

| 4 | Thermocouple | likotoana | 2 |

4.Tlhahlobo pele ho Delivery

Morekisi o na le boikarabello ba ho hlophisa tlhahlobo ea tlhahlobo pele e fihla.