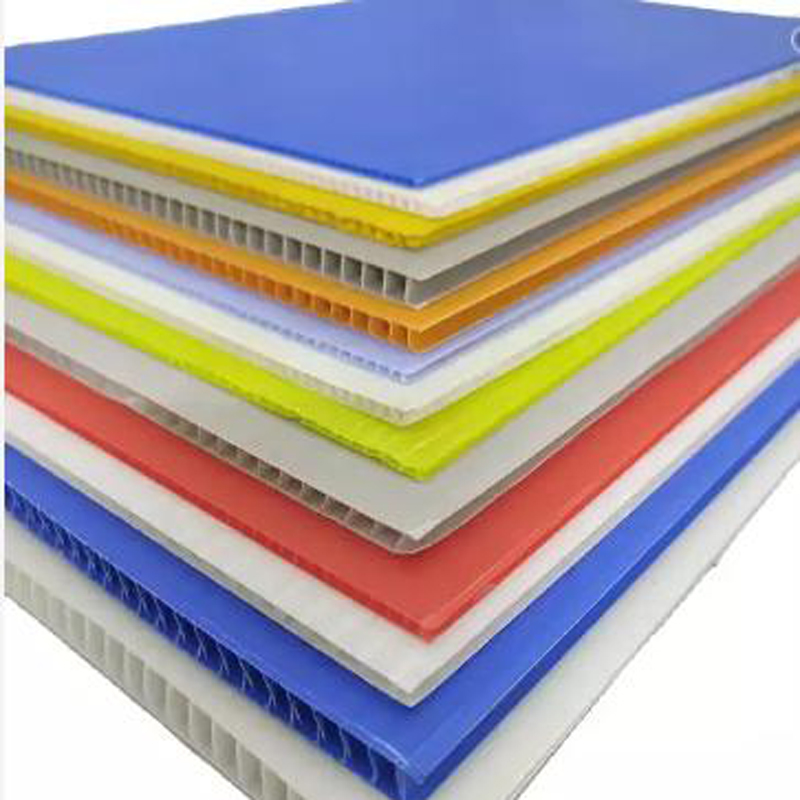

PVC Foam Board Extrusion Machine

Tlhaloso ea Sehlahisoa

Karolo e ka sehloohong ea Plastiki PVC WPC lehong polasetiki composite foam boto extrusion mola / monyako boto Ho etsa Machine / extruder:

- Hangata converter:SIEMENS;

- 2.Full set Siemens likarolo tsa motlakase: Main motor / AC contactor / thermal overload relay / circuit breaker (ho kenyeletsoa sephahla se seholo sa potoloho ea mohala kaofela) / fana ka maikutlo;

- 3.PLC:SIEMENS

- 4.Molaoli oa mocheso: OMRON Japane

- 5.Relay / switch switch:Schneider France

- 6.Twin-Screw: lets'oao le tsebahalang le tsoang Zhoushan, China

- 7.Mould:Letšoao le tummeng la China joalo ka: JC Times/EkO/Weilei

| Lintlha tsa motheo tsa WPC PVC Celuka foam board: | |

| Boitsebiso bo ka sehloohong | PVC/CaCo3/additives |

| Boholo ba boto bo felile | 1220-2050mm(bophara)*2440mm(bolelele bo ka fetolehang) |

| E felile boto botenya mefuta e fapaneng | 3-25mm / 3-30mm / 3-40mm |

| Boholo ba bokhoni ba extruder | 400kgs/h/600kgs/h/800kgs/h/1000kgs/h |

| Phekolo ea holim'a boto | Embossing/phetisetsoa khatiso/lamination/uv coating/CNC fats'e |

| Extruder Mold | SYSJ-80/156 | SYSJ-80/173 | SYSJ-92/188 | |

| Bokhoni ba tlhahiso | kgs/h | 350 | 550 | 650 |

| Botenya ba tlhahiso | mm | 3-25 | 3-30 | 3-30 |

| Lenane la Mechini | |||

| Che. | Lebitso | Qty. | Ela hloko |

| 1 | Screw loader bakeng sa extruder | 1 | |

| 2 | SJZ 80/156 conical twin screw extruder | 1 | |

| 3 | Setsi sa hlobo sa Extrusion | 1 | 1220*2440 |

| 4 | Lethathamo la Vacuum calibration | 1 | |

| 5 | Barakete e phodileng | 1 | |

| 6 | Tlosa yuniti | 1 | |

| 7 | Sesebelisoa sa ho itšeha ka bohale | 1 | |

| 8 | Tracking cutter | 1 | |

| 9 | Mochini o ikemelang oa phetoho | 1 | |

| 10 | Sesebelisoa sa pokello ea lerōle | 1 | |

| 11 | Selaoli sa mocheso oa hlobo | 1 | |

| Mochini o thusang | |||

| 12 | Sehlopha sa SRL-Z Series Mixer | 1 | Matla: 450-550kg/h |

| 13 | Screw loader bakeng sa Mixer | 1 | |

| 14 | Mohlakodi | 1 | Matla: 11kw, 22kw, 30kw |

| 15 | Pulverizer | 1 | Matla: 45kw, 55kw, 75kw |

Lethathamo la mechine le melemo

Mohala oa tlhahiso le mochini o thusang:

| Karolo ea a: Plastiki WPC PVC lehong polasetiki composite foam boto extrusion mola / monyako boto etsa mochine | ||||

| NO. | Lebitso la mochini | Mofuta | Qty. | Hlokomela |

| 1 | Conical twin screw extruder | SJSZ80/156 SJSZ92/188 | 1 sete | e nang le setlankana sa spring up |

| 2 | Sistimi ea taolo ea motlakase | 1 sete | Likarolo tsa motlakase tsa Siemens | |

| 3 | T-moutu | 1 sete | JC Times/Eko/Weilei | |

| 4 | Setsi sa calibration | 1 sete | boholo: 1500 * 600 * 100mm | |

| 5 | Barakete e phodileng | 1 sete | 5000mm(bolelele)*1500mm(bophara) | |

| 6 | Sesebelisoa sa ho hula | 1 sete | 8pairs/10pairs/12pairs | |

| 7 | Sehlopha sa ho kuta ka bolelele le bophara | 1 sete | ||

| 8 | Moqopi oa ho hloekisa lerole | 1 sete | ||

| 9 | Stacker | 1 sete | 2500mm * 1750mm | |

| NO. | Lebitso la mochini | Molemo oa mochine |

| 1 | Automatic feed loader | Ka ho feletseng |

| 2 | Conical Twin Screw extruder | Inovince servo motor, lebokose la li-gearbox tse tummeng le sete e felletseng ea sistimi ea taolo ea motlakase ea SIEMENS,30% HO BOLOKA MATLA, HO TLOHA HO TŠEPILE, BOPHELO BO BOLEELE BA TŠEBELETSO

|

| 3 | T-die | Rala ka borona ka boiphihlelo ba lilemo tse fetang 23 tsa tlhahiso Extrusion le calibration hlobo Litekanyetso tsa tekheniki: a.Unique die sebopeho bakeng sa dihlahiswa sekoti sebelisa core molding optimized phallo tsela ka khomphuta ketsiso ho etsa bonnete ba hore phallo e ts'oanang le e tsitsitseng. b.Sistimi e ikemetseng ea ho laola moea ho leka-lekanya ka potlako ho phalla ha moea ka nako e khutšoanyane ho fumana tlhahiso e tsitsitseng. c.Ho belisoa ha sekoti hantle, molomo le kanale e phallang. |

| 4 | Calibrator | 100mm botenya seipone holim'a calibrator |

| 5 | Bracket e Pholisang | Li-roller tse 9 tsa tšepe tse se nang tšepe |

| 6 | Tlosa mochine | 8-12 lipara holim'a lirolara tsa rabara |

| 7 | Stacker e nang le automatic robert board lift | |

| Mechini e thusang (ka boikhethelo) | ||

| 1 | Mohlakodi | Bakeng sa ho tsosolosa boto e sa tšoanelehang |

| 2 | Sesila | Bakeng sa ho tsosolosa boto e sa tšoanelehang |

| 3 | Motsoako oa Mocheso / Pholiso oa lebelo le phahameng | Bakeng sa ho kopanya lisebelisoa tse tala |

| 4 | Chiller | Ho fana ka metsi a pholileng |

Palo ea lipoleiti tsa ho beha: lipara tse 4

Ho beha poleiti bophara: 600mm

Botenya ba poleiti ea ho beha: 90mm

Bolelele ba poleiti ea ho beha: 1500mm

Ts'ebetso ea kalafo: ho tima le ho futhumatsa + plating e thata ea chromium + ho bentša

Ho pholile ha poleiti ea ho beha: ho pholisa metsi, mocha o entsoeng ka mokhoa o khethehileng oa phallo, phello e ntle ea ho pholisa

Ho phahamisa poleiti ea ho beha: taolo ea hydraulic, taolo ea ho phahamisa e arohaneng

Mokhoa oa ho lokisa oa formwork e kaholimo: screw e ntle ea tokiso

Ts'ebetso ea kalafo ea ho phahamisa likholomo tsa ho lokisa poso: ho tima le ho futhumatsa + plating e thata ea chromium + ho bentsa

Mokhoa oa ho tsamaea ka pele le ka morao oa sethala sa motlakase

Matla a motlakase: 0.37kw

Foromo e fokotsang nmrv-40 / 75-500-0.37

Kakaretso ea mokhoa oa ho fetola bophahamo ba sethala: phetoho ea matsoho

Platform general control control panel e ikemetseng

Phanele ea taolo e entsoe ka sesupo sa matla, sesebelisoa se seholo sa ho tima, konopo ea ho emisa ts'ohanyetso, tachometer, konopo ea tokiso e ntle, v.

| Pvc Foam Board Thepa ea 'Mele | ||

| Ntho ea ho Leka | Yuniti | Sephetho sa Teko |

| Botenya | g/cm3 | 0.35-1.0 |

| Matla a tšepe | Mpa | 12-20 |

| Matla a ho Koba | Mpa | 12-18 |

| Ho kobeha elasticity Modulus | Mpa | 800-900 |

| Boikutlo ba ho Impcting | KJ/m2 | 8-15 |

| Katoloso ea ho senya | % | 15-20 |

| Bothata ba lebopo D. | D | 45-50 |

| Ho Monyeha ha Metsi | % | ≤1.5 |

| Vicar Softening Point | ºC | 73-76 |

| Ho hanyetsa Mollo | Ho Itima Ka Bowena Ka tlase ho metsotsoana e 5 | |