PP Construction Template Extruder Machine / PP Hollow Sheet Board Formwork Building Template Extrusion Line

Mochini oa polasetiki oa PP oa mochini oa moaho oa moaho oa moaho oa PP oa moaho oa moaho oa mohala oa PP hollow bard extrusion mochini

PP kaho template extrusion line polasetiki formwork boto etsa mochine

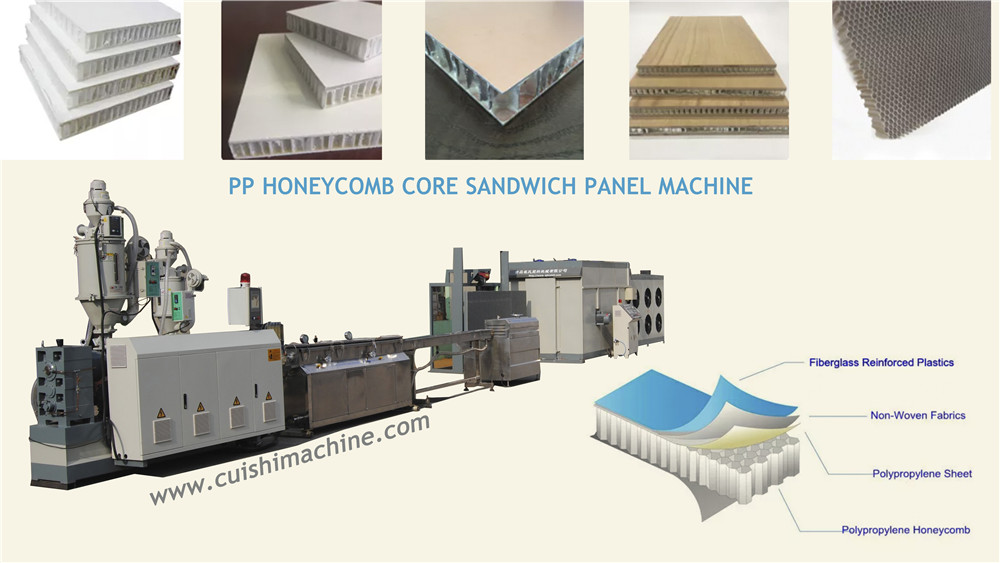

Mohala oa tlhahiso o ka sebelisa lisebelisoa tse tala tsa PP mme oa amohela extruder e le 'ngoe ho hlahisa maqephe a sekoti a likarolo tse tharo.Boleng le litlhaloso tsa lipoleiti tse hlahisoang li finyella litlhoko tsa k'hamphani e batlang.Pp Hollow polasetiki formwork ke mofuta oa lihlahisoa tse bolokang matla le tse tala tsa tšireletso ea tikoloho, pp polasetiki e kopantsoeng le macromolecule nano-technology.Plastic formwork ke sehlahisoa se secha ka mor'a sebopeho sa lehong, tšepe e kopantsoeng ea tšepe, lehong la bamboo-bonding formwork le litšepe tsohle tse kholo.Sebopeho sa polasetiki se se nang letho se boloka matla le ts'ireletso ea tikoloho, 'me se ka nkela sebaka sa tšepe sa setso, sebopeho sa patsi, patsi e sekoere, Ho feta moo, litšenyehelo tsa eona tsa theko e tlase haholo.

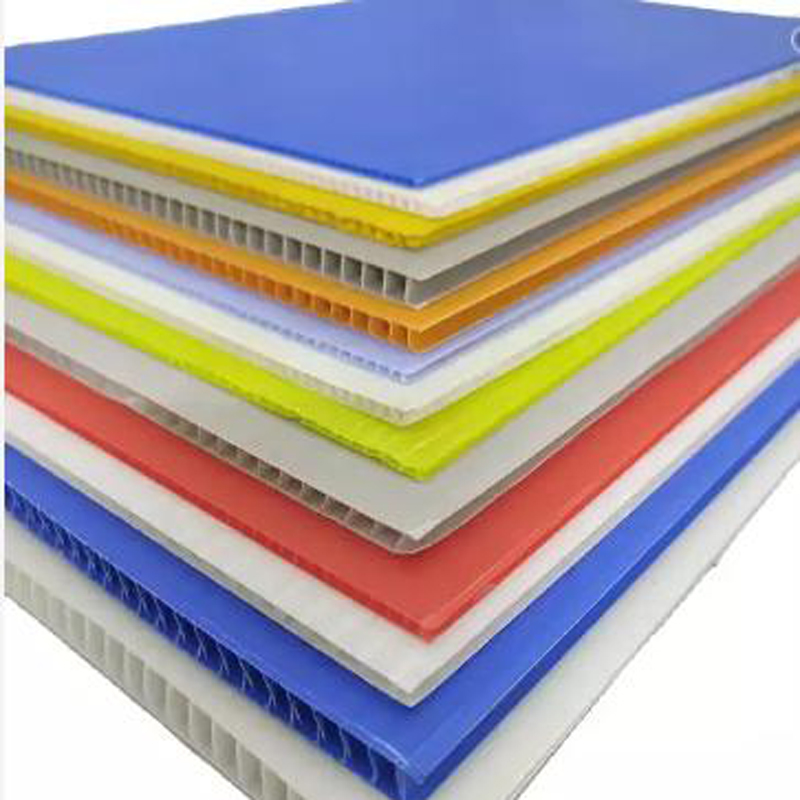

PP Plastic Construction template board e boetse e bitsoa PP hollow form-work

1) E entsoeng ka phofo ea PP e fetotsoeng ka lisebelisoa tse ling ka ho futhumatsa le ho ntša.

2) E nang le linako tse phahameng tsa tšebeliso hape le bopaki ba metsi

3) E ka nkela plywood ea setso sebaka.Eco-friendly ebile ho bonolo ho e kopanya.

4) Foromo ea Kaho ea Plastiki-mosebetsi ke mokhoa oa ho aha meaho ea konkreite e nang le liforomo tsa polasetiki tse ka sebelisoang hape.Mokhoa ona o hloka hoo e batlang e se litsebo tsa mosebetsi, o fumana mosebetsi ka nako ea rekoto, ka tšenyo e fokolang ts'ebetsong.

Lenane la mochini (PP Hollow Sheet Board Construction Formwork Building Template Extrusion Line Single Screw Plastic Extruder Machinery)

| Ntho | Lebitso | Qty |

| 1.1 | Extruder | lihlopha tse peli |

| 1.2 | Hlobo | sete e le 'ngoe |

| 1.3 | Setsi sa Tekanyo | sete e le 'ngoe |

| 1.4 | Mochine oa ho futhumatsa | sete e le 'ngoe |

| 1.5 | Borokho bo phodileng | sete e le 'ngoe |

| 1.6 | Cuuter | sete e le 'ngoe |

Mochini oa ho haha o sekoti oa PP

Mohala oa tlhahiso ea lithempleite tsa PP tsa extrusion o ntlafalitsoe ka katleho ke k'hamphani ea rona ho monya le ho cheka theknoloji e tsoetseng pele ea kantle ho naha le boqapi bo ikemetseng.Botenya ba poleiti bo ka etsoa ho 8-18mm, 'me bophara ba poleiti bo ka etsoa ho latela litlhoko tsa bareki tsa 915mm-1220mm.Sebaka sa eona sa tlhahiso se boreleli ebile se hloekile., Phoso ea boholo bo bonyenyane, e nang le sepekere, ho rera, ho hanyetsa kutu, ho thibela lelakabe le melemo e meng e mengata.

PP Hollow Building Construction Template Board Extrusion Line PP Hollow Formwork Board Extruder Making Machine

Melemo

1. Boima bo bobebe, matla a phahameng, boima bo phahameng, ho hanyetsa tšusumetso, ho hanyetsa ho apara.

2. Bokaholimo bo boreleli, bo khanyang ebile bo hloekile; Phello e entsoeng ka konkreite e ntle bakeng sa mochini oa ho etsa lakane oa pp.

3. Ha ho monya mongobo, ha ho na deformation, ha ho hlobo; nako e telele ho qoelisoa stratification ka metsing, ha ho bubble, lakane boholo botsitso, haholo-holo a loketse bakeng sa ka tlas'a lefatše le dampenment.

4. Bothata bo botle.Mochini oa ho etsa lipampiri oa pp o ka sebelisoa e le sebopeho sa sebopeho se ikhethileng sa cambered.

5. Acid le alkali resistance, corrosion resistance;pp hollow sheet making machine e loketse haholo ts'ebeliso ea boenjiniere libakeng tse lebopong la leoatle, morafong, hammoho le lebota la leoatle.Mochini oa ho etsa letlapa la pp ha o hloke ho etsa kalafo efe kapa efe ea ho boloka le ho boloka sebopeho, se sa silafatse bokaholimo ba konkreite.6. Nako e ka sebelisoang hape bakeng sa mochini oa pp hollow sheet o ka fihla makhetlo a fetang 60, bophelo bo bolelele ba ts'ebeletso.

7. Lihlahisoa tsa litšila li ka sebelisoa hape le ho sebelisoa hape, ho sebelisa litšila ka botlalo.Thepa ena e ka fokotsa litšenyehelo tsa projeke haholo ha e bapisoa le sebopeho sa mapolanka le bamboo formwork.

8. Tšireletso ea tikoloho le ho boloka matla, ha ho na tšilafalo.Ha ho na khase e chefo kapa e kotsi.

9. Hlakola habonolo.Ha ho hlokahale sesebelisoa sa tokollo, ho tlanya feela, theko ea sebopeho sa plywood e tla theoha.Fokotsa lihora tsa mosebetsi le ho potlakisa kemiso ea kaho ka katleho.

10. Ho bonolo ho sebetsa.Ho sakha, ho phunya le ho kokota kaofela li teng.Mochini oa ho etsa letlapa la pp o ka kopanngoa ka mokhoa o otlolohileng le o otlolohileng ka boikhethelo.

11. Ho bonolo ho tlosa.Ho tlosa ho bonolo, ho potlakile ebile ho bolokehile, 'me tšehetso e boetse e bonolo ho e sebetsa, e molemong oa kaho ea mokhatlo, e ntlafatsa ka nepo kemiso ea kaho.

Tlhaloso e ka Sehloohong ea Theknoloji

| Mohlala | SJ120 | SJ150 |

| Lintho tse bonahalang | PP e Fetisitsoeng Boitsebiso | PP e Fetisitsoeng Boitsebiso |

| Bophara ba lihlahisoa | 915/1220mm | 915/1220,915×2 |

| Lihlahisoa tsa botenya | 15-20 limilimithara | 15-20 limilimithara |

| Tlhaloso ea Extruder | 120/3575/35 | 150/3590/35 |

| Bokhoni (Boholo.) | 350-450kg/h | 500-600kg/h |

PP kaho template mohaho formwork PP sekoti boto extrusion

PLASTIC PE PP kaho ea kaho ea mochini oa moaho oa mochini oa extrusion

PE PP mohaho oa template ea mohaho oa mohaho oa ho hlahisa line

PE PP polasetiki formwork boto mochini ho etsa mochine

SEPHEO SE PHAHAMA

TEBELLO MOTLATSI

THEKO LEBAKA

I. Selelekela sa sehlooho

Ho tlisa theknoloji e tsoetseng pele ea machaba, e kopantsoeng le phihlelo ea rona e sebetsang le litlhoko tsa malapeng, mohala ona oa tlhahiso o entsoe le ho ntlafatsoa ke rona 'me o sebelisetsoa ho hlahisa letlapa la polasetiki, ho latela litlhoko tse fapaneng tsa bareki, le ka hlahisa PVC,PP,PE,PS, ABS, likhomphutha, joalo-joalo.

| mohlala | 915/1220 | |

| Boitsebiso bo loketseng |

| PP/PE |

| Max .bophara ba sehlahisoa | mm | 915/1220 |

| Botenya ba sehlahisoa | mm | 16/18 |

| Extruder capacity | Kg/h | 300-500 |

| Bokhoni bo kentsoeng(hoo e ka bang) | kw | 350 |

| Dimension (L*W*H)(approx) | m | 35*2.5*2 |

| Kakaretso ea boima ba 'mele(hoo e ka bang) | t | 10 |