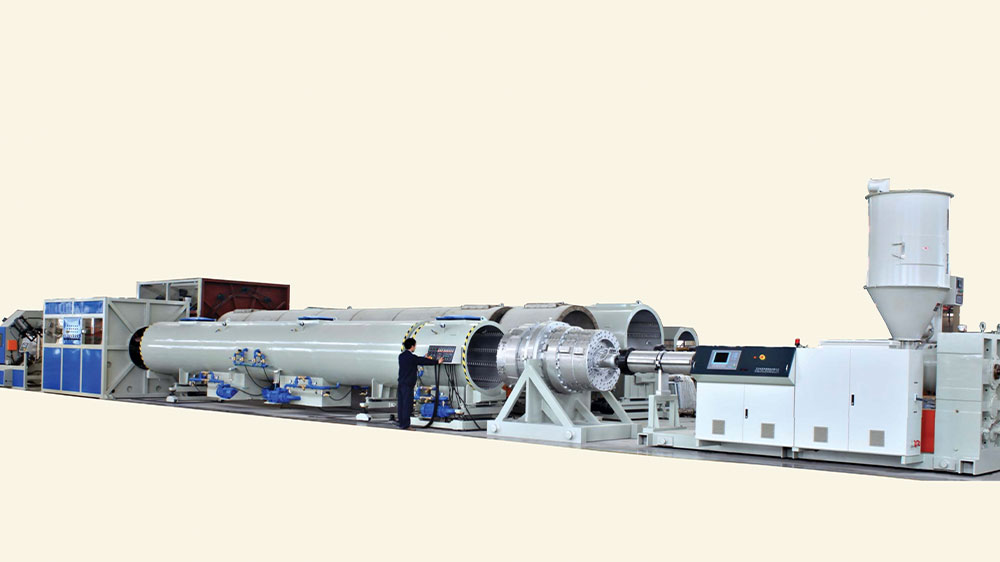

PE PP PC pipe tube extrusion mochini

Tlhaloso ea Lihlahisoa

>> PE Pipe Extrusion Machine e sebelisoa haholo ho hlahisa lipeipi tsa nosetso tsa temo, lipeipi tsa drainage, lipeipi tsa khase, lipeipi tse fepelang metsi, liphaephe tsa likhoele tsa likhoele joalo-joalo.

>> Pipe e na le likarolo tse ling tse ntle tse kang ho thibela ho futhumala, ho tsofala ha botsofali, matla a phahameng a mochine, ho phunyeha ha khatello ea tikoloho, ho hanyetsana le creep, joalo-joalo mohala oa rona oa extrusion o entsoe ka extruder e sebetsang hantle 'me o na le lisebelisoa tse fokotsang lebelo le tlaase. lerata, yuniti ea litekanyetso tsa Gravimetric le sesupo sa botenya ba ultrasonic se ka bokelloa ho latela tlhoko ea moreki ea ho nyoloha ka nepo ea liphaephe.

>> Turn key solution e ka fanoa, joalo ka laser printer crusher, shredder, water chiller, air compressor joalo-joalo ho fihlela tlhahiso ea li-tube tsa boemo bo holimo le bo itekanetseng.

>>Tlhahiso ea Ts'ebetso: Lisebelisoa tse tala+ Mekhahlelo e Meholo → Ho Kopanya → Setsi sa Vacuum Feeder → Pulasitiki Hopper Drier→ Sekoti se le seng → Co-extruder bakeng sa khoele ea mebala le Mekhahlelo e Mengata → Mould → Vacuum Calibration Tank → Fafatsa Tanka ea Metsi a Pholisang → Tlosa → Ha ho Lerōle Cutter → Double/Single disc Winding/ Stacker → Tlhahlobo ea ho qetela ea Sehlahisoa le ho Paka

1. Single Screw Extruder

Extruder e nang le "screw" e le 'ngoe e ka hlahisa mefuta e mengata ea lihlahisoa tsa polasetiki tse kang filimi, phala, boto, braid, lebanta le granules.

2. PE phala shoela hlooho

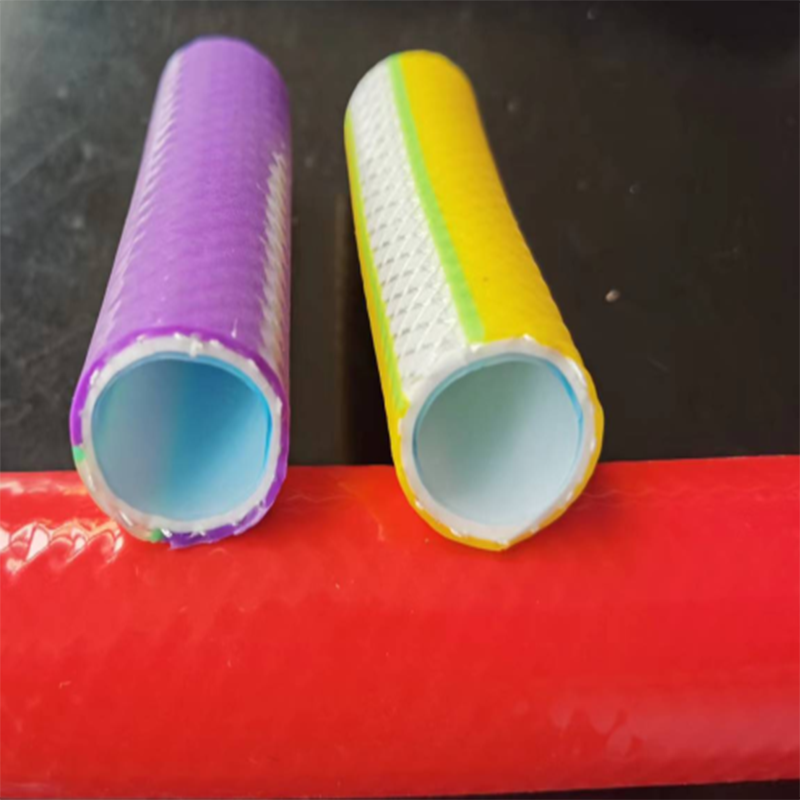

>> E loketse HDPE, LDPE, PERT, PP, PPB, PPH, PP-R, tlhahiso ea lipeipi tsa PS

>> bophara ba bophara ho tloha ho Ø16 ho isa ho Ø1600 mm

>> Homogenity e phahameng ea qhibiliha

>> Khatello e tlase e hahiloe le ka lihlahisoa tse phahameng

>> Sistimi ea ho abela mocha e qhibilihisitsoeng

>> E na le lihitara tsa seramic

>> Koloi ea hlooho ea liphaephe hore e tsamaee habonolo

>> Lihlooho tsa liphaephe li entsoe ho latela litlhoko tsa kopo.

>> Tlhokomelo e bonolo ka lebaka la moaho o ntlafalitsoeng le o netefalitsoeng.

Lilemong tsa morao tjena, 'maraka oa phala ea polasetiki o ntse o tsoela pele ka sekhahla Chaena.Pepe ea PE, PPR le UPVC e bapala karolo ea bohlokoa.Moo nts'etsopele ea pipe ea PE e tsotehang haholo.Pipe ea PE e na le mefuta e mengata ea tšebeliso.phepelo ea metsi le peipi ea khase ke o mong oa mebaraka e meholohali ea likopo.

Re sebelisa mokhoa o akaretsang oa ts'ehetso ea mantlha le lisebelisoa tsa ho fumana sebaka

Moralo oa kanale o qobile sebaka se shoeleng le ho bolokoa.

Moralo o ntlafalitsoeng oa mocha o phallang o o fa matla a matla a ho hanyetsa.

Ho bonolo ho kopanya le ho qhaqha.

Tanka ea ho lekanya Vacuum

>> E loketse tlhahiso ea lipeipi tsa PE

>> bophara ba bophara ho tloha ho Ø16 ho isa ho Ø1600 mm

>> Bolelele ho fihla ho 12000mm

>> 304 tšepe e sa hloekang e nang le bokaholimo bo ka ntle bo pentiloeng

>> Li-sprays tse khethehileng tsa metsi li sebakeng se setle sa ho pholisa phala hantle

>> Lipeipi tse khethehileng le tse bonolo tse fetotsoeng bakeng sa bophara bo bong le bo bong ba phala

>> Lipompo tsa vacuum tse kentsoeng le lipompo tsa metsi li ka sebetsa ntle le tlhokomelo nako e telele

>> Libate tse pholileng tse khethehileng li ka etsoa bakeng sa tlhahiso e khethehileng ea extrusion

Tlosa mochine

>> Pipe e tloha ho Ø16 ho isa ho Ø1600 mm

>> Matla a ho hula a phahameng ntle le ho lahleheloa ke sebopeho sa lipeipi

>> E na le liboko tse 2, 3, 4, 6, 8,10 kapa 12 ho latela ts'ebeliso.

>> Ho khanna koloi ea servo bakeng sa ho fana ka torque e tsitsitseng le ho matha

>>Motorized positioning ea popane e ka tlaase

>> Ts'ebetso e bonolo

>> Tšireletso e koetsoeng ka botlalo bakeng sa polokeho e kholo

>> Li-conveyor tsa ketane tse nang le liphaephe tse khethehileng tsa rabara holim'a liketane tse se nang letšoao phaepeng.

>> Ho lumellana le lebelo la screw ea extruder ho lumella tlhahiso e tsitsitseng nakong ea ho fetola lebelo la tlhahiso

Sisteme ea ho khaola

>> Khokahano ea othomathiki ka lebelo la extrusion

>> Planetary e nang le disk le milling cutter bakeng sa ho seha le ho khahleha

>> Chip-free e na le lehare la disk ho netefatsa sebaka se sehang se se nang lerōle

>> Phanele ea taolo ea skrineng ea ho ama

> Metsamao eohle e tsamaisoa ka enjene ebile e laoloa ke control panel

>> Ho thibela lipeipi ka ho sebelisa clamping ea bokahohle bakeng sa ts'ebetso e bonolo

>> Mofuta oa yuniti ea ho itšeha o khethoa o ipapisitse le phala

>> Litlhoko tsa tlhokomelo e fokolang

>> Mochini o koetsoeng ka botlalo le o sirelelitsoeng bakeng sa polokeho e kholo

Li-Paramenters tsa Lihlahisoa

| Bophara ba bophara(mm) | Mohlala oa Extruder | Max.Bokhoni(kg/h) | Max.lebelo la mola(m/min) | Matla a Extruder(KW) |

| Ф20-63 | SJ65/33 | 220 | 12 | 55 |

| Ф20-63 | SJ60/38 | 460 | 30 | 110 |

| Ф20-63 Dual | SJ60/38 | 460 | 15x2 | 110 |

| Ф20-110 | SJ65/33 | 220 | 12 | 55 |

| Ф20-110 | SJ60/38 | 460 | 30 | 110 |

| Ф20-160 | SJ60/38 | 460 | 15 | 110 |

| Ф50-250 | SJ75/38 | 600 | 12 | 160 |

| Ф110-450 | SJ90/38 | 850 | 8 | 250 |

| Ф250-630 | SJ90/38 | 1,050 | 4 | 280 |

| Ф500-800 | SJ120/38 | 1,300 | 2 | 315 |

| Ф710-1200 | SJ120/38 | 1,450 | 1 | 355 |

| Ф1000-1600 | SJ90/38 SJ90/38 | 1,900 | 0.6 | 280 280 |