Mochini o etsang lipeipi tsa masenke a HDPE habeli

Sistimi ea ho futhumatsa ntle le tlhokomelo e nang le phallo e phahameng ea metsi

Ho fetoha ha mohlahare oa sebopeho ka potlako

Mehlahare e mengata ea hlobo

Matšeliso a iketsang a papali ea Formback

mokhoa oa ho futhumatsa o sa hlokeng tlhokomelo

Libaka tse fapaneng tsa vacuum tse nang le maemo a fapaneng

Laola ka skrine ea ho ama

mocha o nang le ts'ebetso ea ho bula kapele le theknoloji ea "Zoom".

Mehlahare e fokolitsoeng boima ba 'mele

Bolelele ba lisebelisoa tse khutšoane

Phello e phahameng

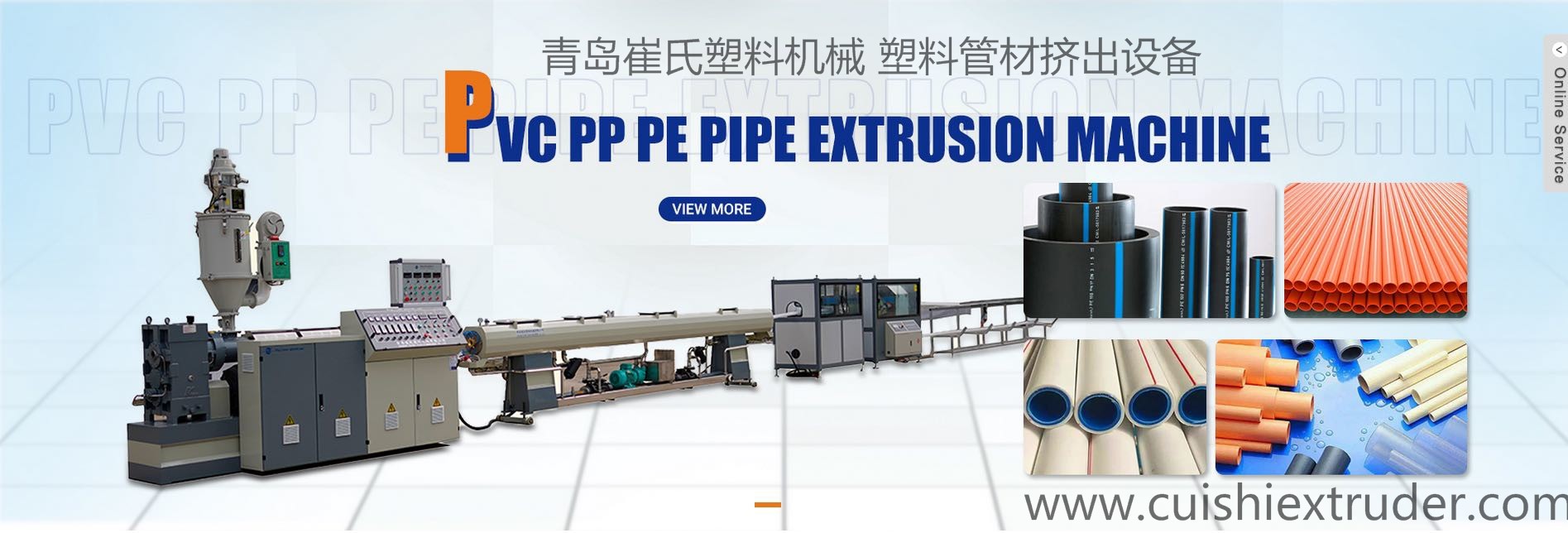

phala ea masenke e sebelisoa haholo bakeng sa tsamaiso ea metsi.Ke mohala o laoloang ke komporo ka botlalo.E na le matla a phahameng le a tsitsitseng a tlhahiso, le ts'ebetso ea othomathike haholo.Bakeng sa HDPE, o ka khetha "screw extruder" e sebetsang hantle haholo.Bakeng sa PVC, o ka khetha conical twin-screw extruder kapa parallel twin-screw extruder.Sistimi ea ho etsa e na le hlobo le corrugator.

Li-block tsa hlobo li ka fetoloa habonolo 'me li na le tsamaiso ea ho pholisa moea kapa metsi.Ts'ebetso ea ho letsa e mocheng.Ho itšeha ho holimo ho ka tiisetsoa ka mochine oa ho itšeha.Mohala oa tlhahiso o ka boela oa hlomelloa ka sistimi ea SIEMENS PLC.

| Mofuta oa Pipe | Diameter(mm) | HDPE Output(kg/h) | MAX Lebelo(m/min) |

| CS-160 | 50-160 | 300-400 | 4 |

| CS-500 | 200-500 | 600-700 | 3 |

| CS-800 | 200-800 | 1000-1100 | 3 |

| CS-1200 | 600-1200 | 1000-1200 | 1 |

¢200-¢800PE/PPMochini oa lipeipi tse entsoeng ka marako a mabeli

DWC800 lebelo le phahameng la ho pholisa metsi leboteng le habeli la peipi ea masenke Sebopeho sa lisebelisoa le tlhaloso ea tlhophiso

Mohala oa tlhahiso o ka hlahisa PE / PP marako a mabeli a marako a nang le bophara bo ka ntle ba 800mm.Matla a kentsoeng a mohala oa tlhahiso ke 600kw mme matla a tloaelehileng ke 360KW.Litlhoko tsa metsi a pholileng: ≤ 15 ℃, 0.5mpa, 0.3m3 / min.Litlhoko tsa moea tse hatelitsoeng: 1.3m3 / min, ≥ 0.6MPa

Boholo ba mochini: 45m×7.0m×4m (L*W*H)

Kenyelletso e khuts'oane ea tlhophiso ea lisebelisoa le ts'ebetso

1.SJ-90/36 SINGLE SCREW EXTRUDER bakeng sa lera le ka hare la 1SET

1.1 screw bophara: 75mm;

Karo-karolelano ea bolelele ba 1.2 ea sekoti: 36: 1;

1.3 screw speed: 9-90r / min; 1.4 thepa ea screw le barrel: 38CrMoAlA, nitriding le ho sila;

1.5 matla a ho khanna: 132KW, DC motor, DC lebelo la taolo;

Sebopeho sa sekoti sa 1.6: sekoahelo se phahameng sa tšireletso se nang le karolo e khethehileng ea ho kopanya, e ntlafatsang haholo boleng ba polasetiki le tlhahiso;

Sebopeho sa moqomo oa 1.7: moralo oa asymmetric slotted barrel o amohetsoe, 'me sehokelo sa phepelo se na le sistimi e pholileng ea metsi e nang le taolo ea mocheso o ikemetseng ho habeli katleho ea phepelo ea karolo ea phepelo;

1.8 gearbox ea phokotso: lebokose la gear la phokotso le nka sebopeho se emeng, 'me mokhoa oa ho pholisa o qobelloa ho potoloha pholileng ea oli, ka sistimi e potolohang ea metsi.Torque e phahameng, lerata le tlase, lisebelisoa tsa leino le thata, ts'ebetso ea ho sila, hammoho le ho kenya letsoho ho matla;

2.SJ-120/33 SINGLE SCREW EXTRUDER ONE SET

2.1 screw bophara: 120mm;

Karo-karolelano ea bolelele ba 2.2 ea sekoti: 33: 1;

2.5 matla a ho khanna: 160KW, DC motor, DC lebelo la taolo;

3.DWC-800HIGH LEbelo LA METSI A PHOLISA HO SEBELISA HO FUMANA

3.1 Mochini o entsoeng ka masenke o hlophisitsoe ka sebopeho se secha se otlolohileng.Ha ho bapisoa le mohaho o otlolohileng, mochine oa ho etsa o na le boima bo phahameng, setsi se tlaase sa matla a khoheli, ts'ebetso e tsitsitseng haholoanyane le ts'ebetso e bonolo le tlhokomelo;

3.2 mochini o entsoeng ka makotikoti o amohela sebopeho se pholileng sa metsi ka kotloloho, se etsang hore sebaka sa pholileng se potolohe ka har'a mojule ka lebelo le phahameng la phallo mme se na le ts'ebetso e phahameng ea ho pholisa, e le ho netefatsa tlhahiso e phahameng ea mohala oa tlhahiso, ho fihla ho 1800 kg / h (HDPE).

3.3 moralo o mocha oa sebopeho sa mochini o bopang o etsa hore liforeimi tse ka letsohong le letšehali le le letona li bulehe le ho koaloa ka bolokolohi, e leng se tlisang boiketlo bo boholo bakeng sa tlhahiso e tenyetsehang.

Li-racks tse ka ho le letšehali le tse ka ho le letona li ka buloa le ho koaloa ka ts'ebetso e bonolo ha u fetola li-module tsa litlhaloso tse fapaneng kapa ho emisa ho se na mojaro, e leng se ka qobang mosebetsi o boima oa ho fetola o bakoang ke "ho tšoara" hlooho ea lefu ka mochine oa ho etsa likoti, ho ntlafatsa boiketlo ba tšebeliso le tlhokomelo ea lisebelisoa;

3.4 moralo o ikhethileng oa pina e tsamaisang mojule oa ho etsa o ka etsa hore mojule oa ho etsa o tsamaee ka mahlakore a matle le a mabe;

3.5 bophahamo ba bohareng ba mochine oa ho bopa bo tsitsitse, 'me ha ho hlokahale ho lokisa foreimi kapa sethala sa mochine oa ho bopa, kahoo ho bonolo ho sebelisa le ho sebetsa;

Theknoloji ea tlhahiso ea 3.6 e tsoetseng pele ea patented module e nolofalletsa mocha oa ho pholisa le mocha oa vacuum ka mojulung o nepahetseng oa sekoti hore o behoe ka nako e le 'ngoe, ka matla a phahameng a mojulu le bophelo bo bolelele ba ts'ebeletso, e le ho netefatsa tlhahiso ea boleng bo holimo le e sebetsang ea liphaephe;

3.7 Sisteme ea othomathike ea lubrication e na le lintlha tse ngata tsa ho lubrication, tse ka behang nako le maqhubu a ts'ebetso ea othomathiki;

3.8 boemo ba mochini o bopang bo tla lokisoa ka motlakase le ho hlomelloa ka lisebelisoa tse phethahetseng tsa ho metha le maikutlo;Hlahisa ka nepo palo ea tokiso ea boholo bo bong le bo bong.

3.9 mochini o etsang o na le ts'ebetso ea ho tsoa maemong a tšohanyetso;

3.10 Sistimi ea taolo ea PCC e tsebahalang ea machabeng e nka leano la taolo la modular, le nang le tšebelisano e phahameng, taolo e nepahetseng le ts'epo e phahameng.

4. CS1000 TYPE WATER COOLING TANK;

4.1 tanka ea metsi a pholileng e bulehileng lehlakoreng, e sebetsang le ho e hlokomela habonolo;

4.2 'mele oa lebokose o entsoe ka tšepe e sa hloekang;

4.3 mosebetsi oa ho laola mocheso oa metsi le boemo ba metsi;

4.4 tanka ea metsi e na le lisebelisoa tse sebetsang tse tataisang ho fokotsa ka katleho ho hanyetsa ha liphaephe;

4.5 sesebelisoa se matla sa ho omisa ho tlosa metsi a pholileng ka ho feletseng holim'a phala;

5. ONE beha 1000 othomathike chip mochini o sehang mahala

5.1 chip ea mahala ea ho itšeha, mochini oa ho fepa ka hydraulic, ho nepahala ho phahameng, ho netefatsa karolo e boreleli;

5.2 mokhoa o thusang oa ho lemoha ho netefatsa hore sehahi se fumaneha ka nepo sebakeng sa ho itšeha;

5.3 ho fetola ka tsela e iketsang le ka letsoho;

5.4 mokhoa oa ho koala: ho koala moea;

Sistimi ea taolo ea 5.5 PCC e laoloa ebile e hlomelloa ka sebopeho se tloaelehileng sa puisano ho tsamaisa khokahano le lisebelisoa tse tsamaellanang.

6. CS800 STACKER ONE SETE

6.1 bophahamo ba rack e se nang letho e amohela phetoho ea motlakase, e leng bonolo ho sebetsa;

6.2 fana ka lisebelisoa tsa ts'ireletso tse nahannoeng ho netefatsa polokeho ea sebaka sa tlhahiso.

7. PIPI E SEKOFU E HLAHANG MEFUPI

DN/ID200mm MOLDS BLOCK, mojule, hlooho ea moqomo oa boholo

DN/ID300mm MOLDS BLOCK, mojule, hlooho ea moqomo oa boholo

DN/ID400mm MOLDS BLOCK, mojule, hlooho e lekanang le boholo ba letsoho

DN/ID500mm MOLDS BLOCK, mojule, hlooho ea letsoho e lekanang

MOSULE OA HO HLOMELA LIHLOOHO

7.1.1 mochine o entsoe ka motsoako o khethehileng oa aluminium o nang le conductivity e phahameng ea mocheso, boima bo phahameng le ho hanyetsa ho apara ho phahameng;

7.1.2 mojule oa ho etsa o amohela mokhoa oa bohlokoa oa ho lahla khatello, o nang le sebopeho se teteaneng le botsitso bo phahameng ba mocheso;

7.1.3 phekolo e khethehileng ea karolo e ka hare ea mojule ha e ntlafatse feela matla le boima ba mojulung, empa hape e thusa ho theha ka mokhoa o phethahetseng oa ripple.

7.1.4 phallo ea moea ea vacuum le mocha o pholileng oa metsi o nang le karolo e kholo ea phallo e netefatsa ts'ebetso e tsitsitseng, ea boleng bo phahameng le e sebetsang hantle ea tlhahiso.

7.2 Spiral kanale extrusion shoa

7.2.1 bakeng sa moralo oa 'nete o ikemetseng oa lefu la hlooho, ha o fetola litlhaloso, tlosa feela likarolo tse' maloa tse kopanyang tsa hlooho ea lefu 'me u hule thapo e futhumatsang ea hlooho ea lefu ho tlatsa sebaka sa hlooho ea lefu la tlhaloso e' ngoe ntle le phetoho e sa hlokahaleng.Sena ha se etse feela hore ho be bonolo le ho potlakisa ho nkela sebaka se boletsoeng, empa hape se tiisa ho nepahala ha lefu le ho ba le bophelo bo bolelele ba tšebeletso ka ho qoba ho qhaqha khafetsa le ho bokana ha likarolo tsa lefu;

7.2.2 mocha o mocha oa spiral die o ka fokotsa ka katleho ho hanyetsa phallo ea thepa le ho ntlafatsa phello ea polasetiki ka ho khutsufatsa haholo bolelele ba mocha.

7.3 Baki e ncha ea alloy alloy e pholileng ea metsi

Execooc e nang le sebopeho se secha sa ™ Aluminium alloy cooling sage baki ea metsi e na le ts'ebetso e ntle haholo ea ho sesa le phello e ntle ea ho pholisa ka ho khetha hape lisebelisoa tsa alloy tsa aluminium le ho sebelisa mokhoa o mocha oa kalafo ea mocheso.E ka hlokomela motsoako o phethahetseng oa mocheso o phahameng oa mocheso o bobebe le matla a phahameng, 'me ka katleho a hlola liphoso tsa ts'ebetso e tlase ea tsidifatso ea baki ea metsi e pholileng ea tšepe e sa hloekang le baki ea ho roala hamonate ea baki e tloaelehileng ea aluminium alloy pholileng.

Hape re na le moralo oa mochini o otlolohileng