Full othomathike Plastic fatše metsi seepage pipe ho etsa mochine

Mochini oa ho etsa li-tubing tsa polasetiki o ikemetseng o boetseng o reha Mochini oa ho etsa phala ea polasetiki, o sebelisoa haholo PP kapa PE joalo ka lisebelisoa tse tala, o eketsa antistatic agent, anti-aging agent le li-additives tse ling, hape o ka sebelisa thepa e sebelisoang hape ebe o e kenya ka har'a phala ea net. .

Mochini oa polasetiki oa letlooa o thehiloe ho HDPE, PP joalo ka thepa e ka sehloohong e tala, ka extrusion, e ts'oanang le hlobo e khethehileng e etsang lebota la lesoba la phala ea polasetiki.Lihlahisoa tsa eona li sebelisoa haholo-holo setsing sa filthara, serapeng, ho lema, joalo ka tšimo ea metsi a fatše.

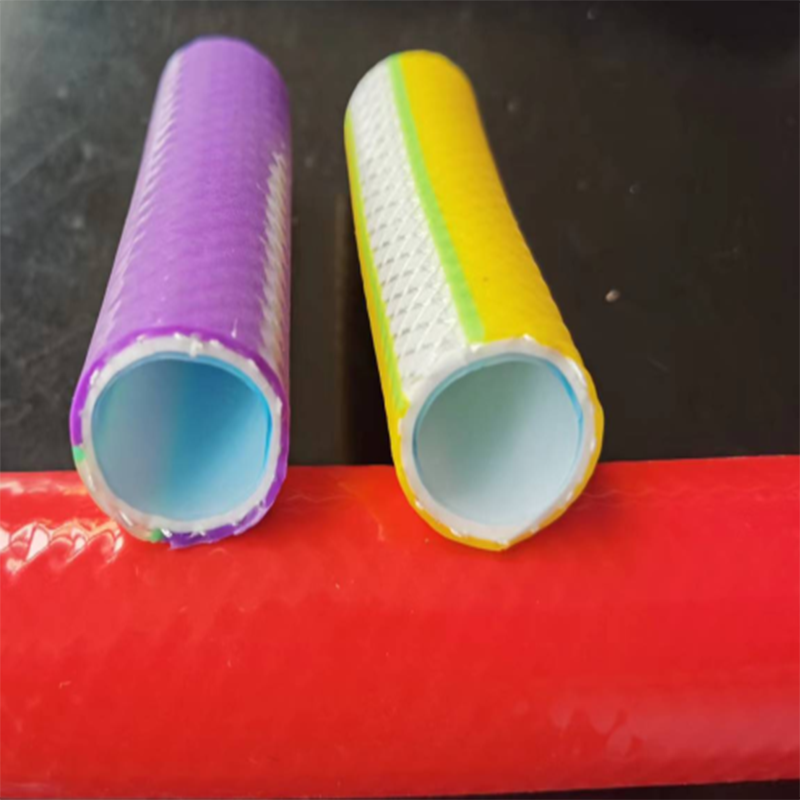

Plastiki mesh tubing e sebelisoa haholo bakeng sa karohano ea thepa, ts'ehetso ea meralo, polokelo le lits'ebeliso tse ling tse ngata.Li-tubes tse fetisitsoeng li entsoe ka thepa ea PP kapa PE 'me li tla ka bophara bo fapaneng, bolelele, li-apertures le matla a ho lumellana le kopo leha e le efe.Li-tubes tse fetisitsoeng li fumaneha ka bophara ba lisenthimithara tse 5 'me li fana ka sebopeho se tsitsitseng, sa cylindrical.Hape, ts'ebetsong, tube e ka eketsa likarolo tse ngata tsa marang-rang a matle kapa lisebelisoa tse sa lohiloeng ho etsa lisebelisoa tse eketsehileng.

Mohala oa tlhahiso ea phala ea polasetiki ea PP PE ke moralo oa rona o mocha oa sehlahisoa mme o ntlafalitsoe ke rona ka theknoloji e tsoetseng pele le ho latela maemo a lapeng.Moralo oa sebopeho sa mohala o na le boleng bo botle, o ka tšeptjoang, o sebetsa hantle, o tlatsitsoe sekheo sa lapeng, mme sebakeng sa thepa ea kantle ho naha.

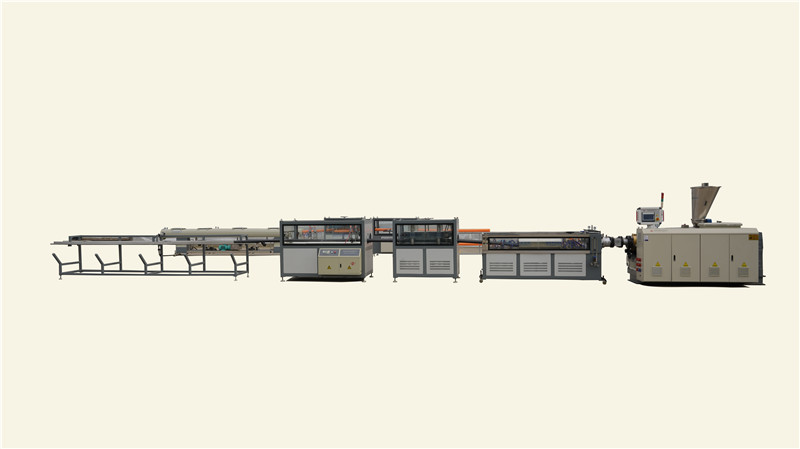

Se latelang ke setšoantšo sa rona sa karolo ea mochini

sj65/30 peipi ea peipi e le 'ngoe ea sekoti sa polasetiki ea extruder

Kenyelletso e khuts'oane ea screw extruder e le 'ngoe

The single-screw extruder haholo-holo e sebelisetsoa ho ntša thermoplastics tse kang polyvinyl chloride e bonolo le e thata, polyethylene, joalo-joalo E ka sebetsana le lihlahisoa tse sa tšoaneng tsa polasetiki, tse kang filimi e phatlohileng, tube e extruded, platen, ribone e hulang, joalo-joalo, e boetse e sebelisetsoa ho qhibiliha granulation.

Li-extruder tsa "screw" tse nang le "single-screw" ka kakaretso li etsa qeto ea bolelele ba bolelele bo sebetsang ba mararo ho latela bophara ba screw, screw pitch, le botebo ba screw, e 'ngoe le e 'ngoe e arotsoe ka karolo ea boraro e arotsoe ka karolo e tsamaisang, karolo ea khatello le karolo ea metering.Karolo ea ho tsamaisa e qala ho tloha khoele ea ho qetela ea boema-kepe ba phepelo, haholoholo ho futhumatsa, ho petetsa le ho phethela mosebetsi oa ho tsamaisa.Karolo ea bobeli ke karolo ea compression.Mocheso o lokela ho fihla tekanyo ea polasetiki ea thepa, eo haholo-holo e hatelitsoeng ho tsamaisa thepa ea polasetiki ho ea karolong ea boraro.Karolo ea boraro ke karolo ea metering, moo thepa e bolokang mocheso oa polasetiki 'me ka nepo le ka bongata e tsamaisa thepa e qhibilihisitsoeng ho hlooho ea mochine.

Morero o ka sehloohong oa screw extruder e le 'ngoe

Pipe extrusion: e loketse liphaephe tsa PP-R, lipeipi tsa khase tsa PE, liphaephe tse hokahaneng tsa PEX, liphaephe tse kopaneng tsa aluminium-polasetiki, liphaephe tsa ABS, lipeipi tsa PVC, lipeipi tsa mantlha tsa silicon tsa HDPE le liphaephe tse fapaneng tse kopaneng tse kopaneng.

Sheet extrusion: e loketse bakeng sa extrusion ea PVC, PET, PS, PP, PC le lintlha tse ling le maqephe.Extrusion ea li-plastiki tse ling tse fapaneng tse kang silika, melamu, joalo-joalo.

Extrusion of profiles: ho lokisa lebelo la extruder le ho fetola sebopeho sa screw extrusion ho ka sebelisoa ho hlahisa litlaleho tse fapaneng tsa polasetiki tse kang PVC le polyolefin.Granulation e fetotsoeng: e loketse ho kopanya, ho fetola le ho ntlafatsa granulation ea lipolasetiki tse fapaneng.

Mohopolo oa moralo oa screw extruder e le 'ngoe

◎ Extrusion ea lebelo le holimo, e fanang ka kotulo e phahameng e ipapisitse le boleng bo holimo.

◎Mohopolo oa moralo oa polasetiki ea mocheso o tlase o netefatsa ho hlahisoa ha lihlahisoa tsa boleng bo holimo.

◎ Moralo o akaretsang oa mehato e 'meli o matlafatsa tšebetso ea polasetiki mme o netefatsa hore ho lokisoa ha extrusion e sebetsang hantle.

◎Sethibelo se khethehileng, moralo o akaretsang oa BM oa ho kopanya ho netefatsa phello ea ho kopanya ea thepa.

◎Tlhahiso e phahameng ea torque, matla a maholo a eketsehileng.

◎ Thepa le shaft li entsoe ka tšepe ea alloy e matla haholo, e kentsoeng ka har'a carburized le ho siloa.

◎Bothata bo phahameng, pheletso e phahameng le lerata le tlase haholo.

◎ PLC taolo e bohlale e ka hlokomela kamano pakeng tsa mechini ea mantlha le e thusang.

◎Ho bonolo ho beha leihlo sebopeho sa mochini oa motho, ho bonolo ho utloisisa ts'ebetso le boemo ba mochini.

◎Mokhoa oa ho laola (sesebelisoa sa ho laola mocheso) o ka nkeloa sebaka ha ho hlokahala.

◎Material ke kalafo ea 38CrMoAL/A nitriding, e sa senyeheng.

◎Ho nepahala ha taolo ea mocheso, ho kopanngoe le ho pholisa moea le ho pholisa metsi.

◎ Moralo o ikhethileng oa lisebelisoa, o nang le sesebelisoa se pholileng sa metsi.

◎ The screw barrel e nang le grooved feeding sleeve e ka tlase e na le ts'ebetso e matlafalitsoeng ea ho fepa, e fanang ka tiisetso bakeng sa ho ntša ka lebelo le phahameng le chai e ngata.

High Speed Extrusion Die and Mold For PE Pipe/hot sale Three-layer PE Pipe Co-extrusion Mold Factory direct sales

1) PE PP phala hlobo e sebelisoa haholo ho etsa PE PP phepelo ea metsi / khase ea phepelo ea metsi, drainage le phala ea merafo le mohala oa phala ea extrusion.

2) ke sesebelisoa sa tlhahiso ea theknoloji e phahameng, le ts'ebeletso e ntle ea meralo, bokaholimo ba phala e boreleli, bophelo bo bolelele ba ho sebetsa.e ka boela ea fetola bophara ba liphaephe le litšenyehelo tsa ho boloka

lihlahisoa tse ka sehloohong

1.PVC, PPR, PE phala extrusion hlobo le ho loketse ente hlobo

2.PVC, PPR, peipi ea PE le ho kenya phala

3.mochine o butsoelang oa polasetiki oa bophara bo boholo le hlobo ea oona

4.ha ho lohiloeng ho hlahisa lefu hlooho